In the previous article, the author introduced the definition and causes of built-up edge, and left a "scratch unsolved case" at the end of the article. In this article, the author will become a great detective, investigate and analyze the "criminal scene", and reveal the mastermind behind the scenes.

Multiple suspects, who is the real murderer?

As described in the previous article, the working condition is to use a PCD drill-ream integrated tool, and on the basis of no pre-processing, start processing from the blank pre-cast hole (the pre-cast hole depth only accounts for 1/4 of the total depth).

Defects appear discontinuously. By recording the number of defects and their analysis over time, the authors found that scratch defects vary with the condition of the blank (different manufacturers), equipment and coolant.

After the problem appeared, the author first found that the scratches were concentrated on the blank of a domestic brand. Thanks to the fact that the equipment also uses a certain imported brand blank, in order to verify the correlation between the blank and the scratches and shield other interference factors as much as possible, the author successively put the blanks from two manufacturers in the quantity of 20 pieces in each group. .

Under the condition that the tools, equipment and coolant remain unchanged in a short period of time, the proportion of domestic blanks with scratches is as high as 60%, while the imported blanks have no scratches.

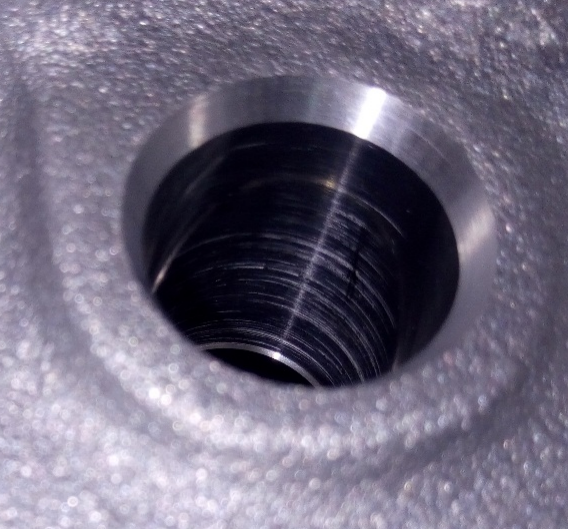

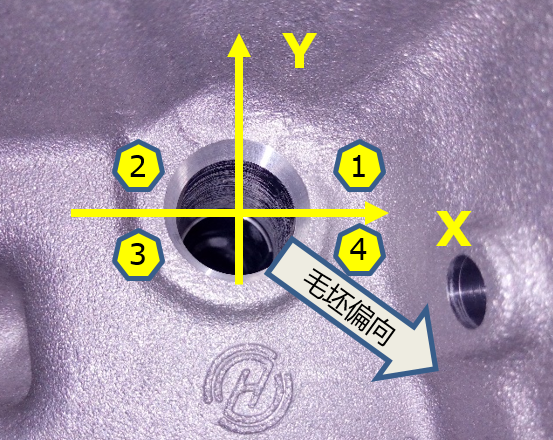

In view of the blank difference, limited by laboratory conditions, the author can only test and compare the blank size. It is found that the domestic blank pre-cast hole has a larger radial allowance, and the center position is offset: the center of the finished hole is established. Coordinate system, the center position of the pre-cast hole is biased towards the fourth quadrant, as shown in the figure above.

The scratches are more obvious in the second quadrant, which has two aspects: first, when the scratches are distributed in a circle, the scratches in the second quadrant are more dense; second, when the scratches are not distributed in a circle , the scratches are concentrated in the second quadrant.

To sum up, the suspect of "No. 1" and the blank is that the larger the cutting allowance, the more likely scratches will appear.

The influence of the equipment is mainly reflected in the rigidity, and the data indicator selects the vibration data during the rotation of the main shaft.

When the scratches first appeared, the author suspected that the rigidity of the equipment was insufficient, especially during the tool retraction process, the vibration intensified due to no cutting load, and eventually the tool tip scratched the hole wall. Thanks to the fact that there are four devices in the same station, we can compare and analyze the impact of device rigidity on scratches.

The maintenance colleagues measured the vibration data of the equipment at a speed of 3000rpm (the tool was processed at 2500rpm). It is very surprising that the larger the vibration data, the lower the probability of scratches. To sum up, the suspicious point of the "Suspect No. 2" equipment: the less rigid the equipment is, the less likely it will be scratched.

When addressing the scratching issue, the authors found that because the four devices in question were using the same centralized cooling, the coolant's impact on it was synchronised.

The author found that the scratch problem has obvious time distribution, but it does not completely coincide with the on-line time of the imported blank. In the process of in-depth investigation, because the time distribution of coolant concentration and PH value (two control indicators of coolant characteristics by the author's unit) did not completely match it, the author almost missed the real "suspect No. 3": Supplement The frequency of the stock solution.

In order to supplement the consumption during processing, it is necessary to add stock solution and RO water to the centralized cooling equipment regularly.

The sharp reduction of the scratch problem, after excluding the influence of imported blanks, is actually highly consistent with the time of "replenishing the stock solution". Compared with the total amount of cooling liquid circulating in the centralized cooling, the supplementary amount of the original liquid is small, which does not necessarily cause changes in the concentration and pH value. However, after each replenishment of the stock solution, the scratching problem is greatly reduced.

The author tried to increase the coolant concentration from 8%-10% to 10%-12%, but the effect was not obvious. Therefore, the authors suspect that an unknown coolant property, other than concentration and pH, affects the formation and disappearance of scratches. To sum up, the suspicious point of "Suspect No. 3" and the coolant: unknown characteristics.

【Case closing time】

Through the investigation of the three "suspected criminals", the author found that they all have "criminal motives" (mechanism of action) and "criminal time" (distribution coincides), but it seems that there is a mastermind behind the scenes to promote the three suspected criminals. . After reasoning, the author believes that the mastermind behind the scenes is Buildup Bump.

The following author restores the whole process of the incident for you: the cause of abnormal scratches is the continuous generation and shedding of the built-up edge on the tool tip. When the built-up edge falls off, the tool tip leaves scratches on the surface of the workpiece due to vibration.

The suspicious points of the three suspects are also explained with the appearance of the built-up edge: when the blank allowance increases, the cutting force and cutting heat increase, which is conducive to the formation of the built-up edge, so the machining of domestic blanks is prone to scratches. mark. Equipment with poor rigidity and large vibration is not conducive to the stable generation of built-up edge, so equipment with large vibration is not prone to scratches.

The characteristics of the coolant suppress the formation of built-up edge, so after replenishing the original liquid, the scratches are greatly reduced. To sum up, because the blank and equipment cannot be changed, when scratches are found, the production team will replenish the stock solution in the centralized cooling.

When the case was closed, the author still had some doubts in his mind: when the scratches occurred intensively every year, it was all in winter; there were four equipments on site, and the processed products, the tools used and the blank brand were all the same as the production line in question. , because it belongs to an expanded production line, its processing parameters and coolant grades are slightly different, but there has never been a scratch problem. Interested readers are welcome to leave a message for discussion.