The author has referred to built-up tumor several times in previous articles. In the turning topic, the author plans to divide it into two phase1.The definition of built-up tumor

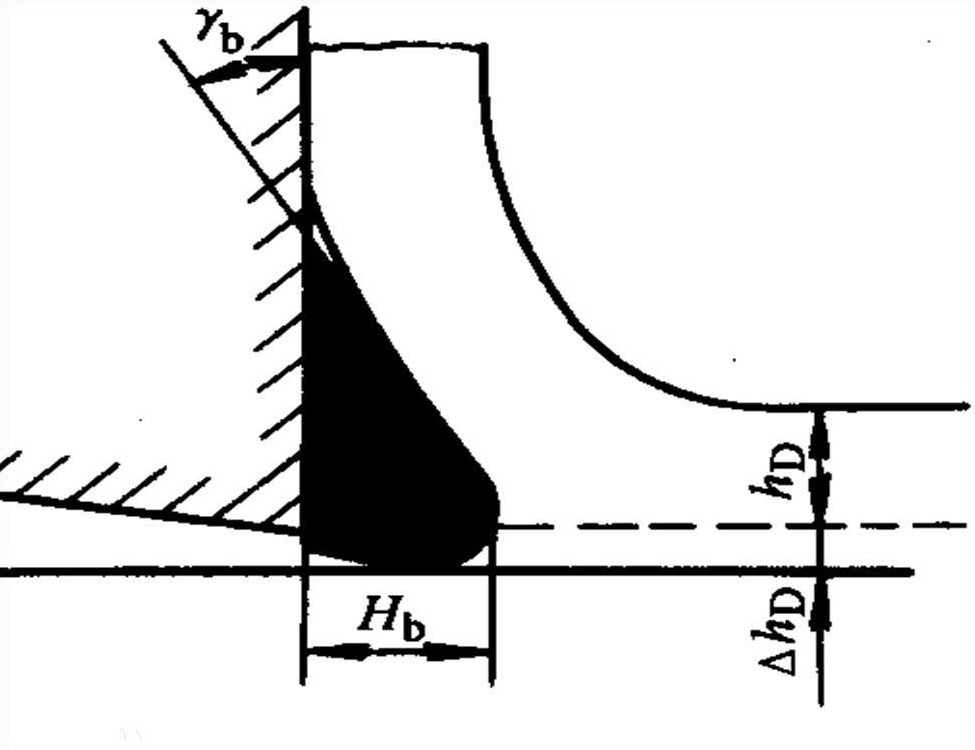

When machining low hardness materials such as aluminum, brass or mild steel, the workpiece material will chemically and mechanically bond to the cutting tool and form a small piece on the rake face of the tool close to the cutting edge A very hard metal, called a built-up edge, also known as a knife edge, shown as the black area in the image below.

2. Causes of built-up tumor

The relevant content in "On the Intrinsic Relationship Between the Formation of Built-up Edge and the Friction Characteristics of the Rake Face" by Liu Wenping et al. is quoted here: The essence of the metal cutting process is the extrusion effect of the cutting layer metal on the cutting edge and the rake face. down, the process of plastic deformation, chip formation and flow out along the rake face.

According to the metal cutting experiment, it can be seen that under the extrusion action of the tool, the metal near the cutting edge firstly deforms elastically, and after the stress caused by the shear stress reaches the yield limit of the metal material, the metal of the cutting layer will move along the cutting edge. The inclined shear plane produces plastic deformation, and then flows out along the rake face, the rake face of the tool produces severe friction due to the extrusion of the chip, so that a thin layer of metal grain fibers close to the bottom surface of the rake face chip After the deformation occurs again, the chips flow out of the rake face.

It can be seen that there is friction on the rake face, which not only affects the cutting deformation, but also provides a powerful condition for the formation of built-up edge. The action of high temperature softens the underlying metal of the chip, and the action of high pressure causes the softened metal to be embedded in the microscopic unevenness of the rake face within a certain range close to the cutting edge, forming a complete fit.

The causes of built-up tumor can be summarized as follows:

1. The bonding phenomenon between the knife and the chip due to internal friction.

When the cold welding (ie bonding) area of the chip is large enough and the temperature reaches a certain value, the cutting layer with zero flow velocity in the stagnant layer is sheared and fractured because the frictional force in the underlying material of the chip exceeds the yield limit of the material The bonding covers the rake face, so that the bottom metal of the chip is cut off and stays on the rake face, becoming a built-up edge, and then the new cutting layer is bonded and accumulated on the basis of the above, and the built-up edge gradually becomes larger.

2. Work hardening of the underlying metal.

The metal near the front of the tool produces shear slip phenomenon due to internal friction, which makes the grains of the bottom layer of the chip have a high degree of fibrosis, which is almost parallel to the rake face. The bottom layer has higher hardness and strength than the previous layer, replacing the cutting edge. Continuing to shear the softer metal layers, the layers build up over and over again to form larger built-up edges. Under the action of external force or vibration, the long built-up edge will rupture and fall off locally, and then grow and fall off repeatedly. Without hardening, the underlying metal cannot settle stably on the rake face and form a built-up edge.

3. Appropriate cutting temperature and pressure

Proper cutting temperature and pressure can maintain the bonding and hardening phenomenon of the underlying metal. If the temperature is too low, it is not enough to cause bonding; if the temperature is too high, the built-up edge will lose its hardness and strength due to work hardening, and will be carried away by the flowing chips until it completely disappears and falls off.

3. The effect of built-up tumor

advantage

1. Instead of cutting

The built-up edge has high hardness, which is generally 2~3 times that of the material to be processed. It can be processed in place of the cutting edge and has a certain protective effect on the cutting edge.

2. Reduce cutting force

The built-up edge increases the actual rake angle of the tool and reduces the cutting force.

shortcoming

1. The built-up edge forms, grows and falls off periodically, resulting in cutting vibration.

2. After the built-up edge is broken, part of it flows into the contact area of the tool and workpiece, forming a "pear groove" on the surface of the workpiece, making the surface of the workpiece rough. Debris can also become embedded in the workpiece surface and cause hard spots that can accelerate tool wear.

Fourth, the measures to inhibit the built-up tumor

1. Avoid the medium-speed zone where built-up edge is likely to occur;

2. Normalizing or quenching and tempering the workpiece material to increase the hardness and reduce the plasticity;

3. Increase the rake angle of the tool, reduce the feed rate, improve the grinding quality of the tool surface, and use cutting fluids with good lubricating properties and other measures.

【Case Explanation】

PCD (namely synthetic diamond) tool, with its low friction coefficient and sharp edge characteristics, produces extremely small cutting force and cutting heat when machining aluminum, which does not meet the conventional conditions for generating built-up edge.

However, the author encountered discontinuous surface scratches many times in the process of machining aluminum parts with PCD tools for many years. Some scratches are caused by the secondary cutting of chips by the tool. For specific cases, please refer to the previous article "Influence of residual chips in the workpiece and its elimination method", but there are also some working conditions caused by scratches, and there is no chip removal. difficult question.

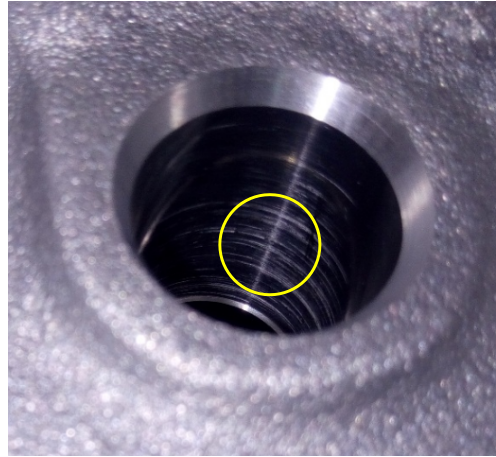

For example the scratches shown in the picture below:

The scratches shown are under the condition of using a PCD drill-reamer integrated tool, no pre-processing, and starting from the blank surface. Defects appear discontinuously and vary with the condition of the blank (different manufacturers), equipment and coolant.

In the next article, the author will become a "big detective" and lead readers to unravel the "scratch case"!