In the last article, the author explained the causes of chips in principle, and introduced the common types of chips. In this article, the author 1.The concept of shear angle

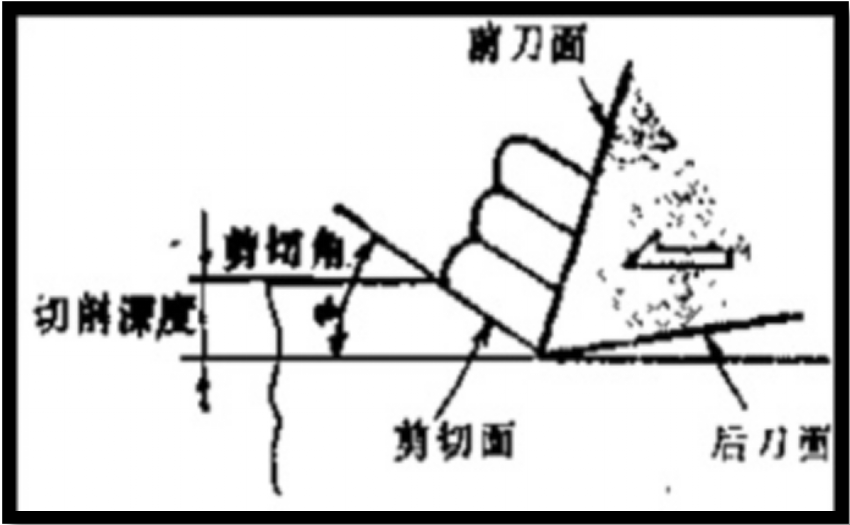

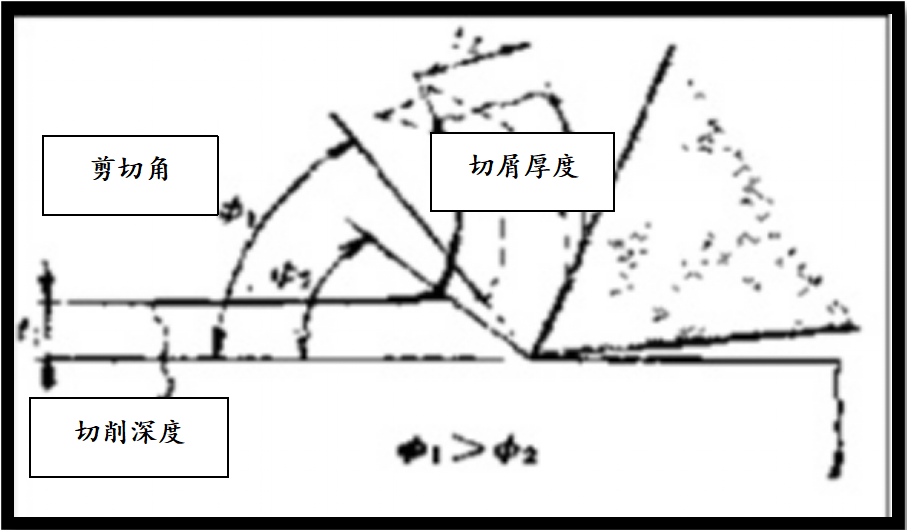

When talking about chip breaking, the concept that has to be mentioned is the shear angle. As shown in the figure below, the angle between the shear plane and the cutting speed direction is called the shear angle. The shear angle indicates the shearing direction of the cutting unit and is one of the important parameters to explain the cutting deformation.

The shear angle can be expressed by the following formula:

TanΦ=(t1/t2)cosγ/[1-(t1/t2)sinγ]

Where: Φ—shearing angle; γ—rake angle of cutter; t1—cutting depth; t2—chip thickness;

From the above formula, we can see that when the shear angle increases, the chips become thinner, the deformation decreases, and the required cutting force is small, so the cutting is easy to carry out. Therefore, the sharpness of the tool depends on the shearing. the size of the corners.

1. Form of chip breaking

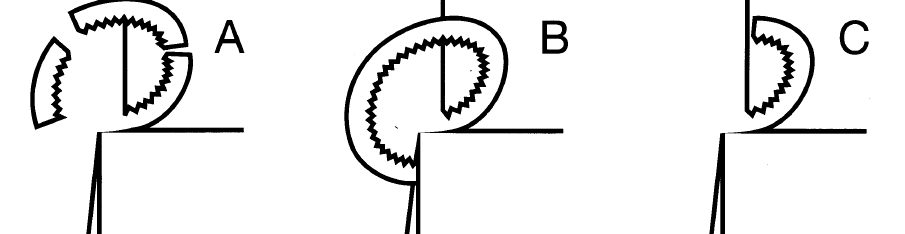

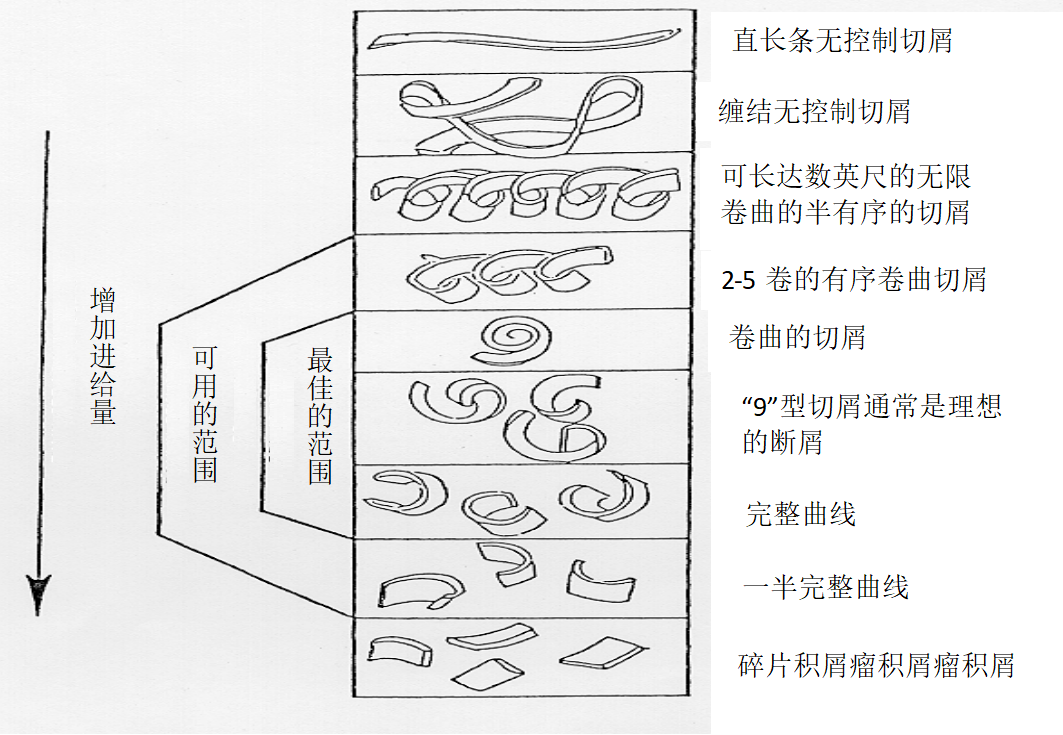

As shown in the figure below, there are 3 types of chip breaking:

A Self-breaking chip (the best form of chip breaking)

B The chip hits the tool and breaks

C. The chips touch the workpiece and break (not advisable and should be avoided)

3. Chip breaking factors

1. Tool rake angle and cutting speed

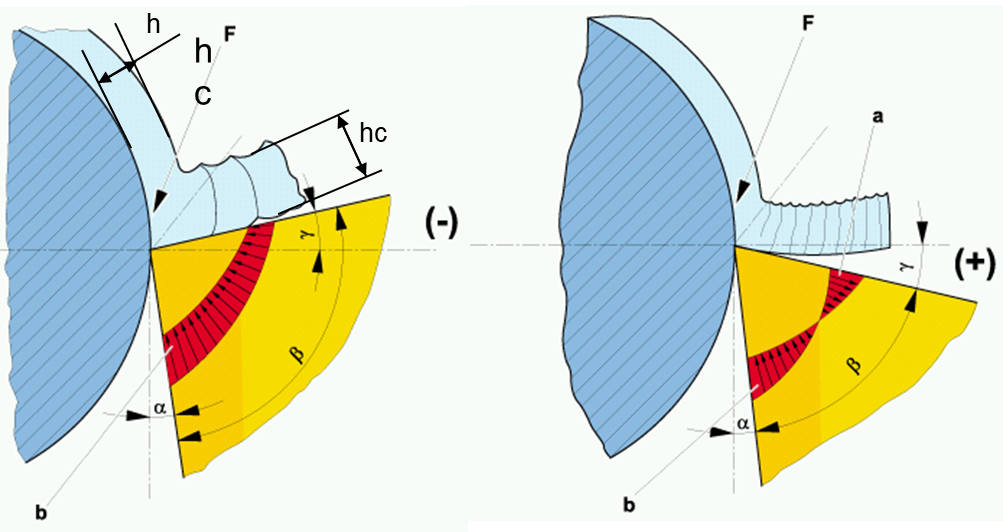

A concept is introduced here: chip compression ratio = hc/h. The larger the value of the compression ratio, the easier it is to break the chip. But at the same time the cutting resistance is also increased.

The compression ratio is related to the linear velocity Vc. When Vc decreases, the compression ratio increases, so reducing the linear velocity is also beneficial for chip breaking.

The compression ratio is also related to the rake angle. When the rake angle decreases, the chip deformation is large, and the compression ratio increases, which is conducive to chip breaking.

2. Main declination angle

The larger the entering angle, the easier it is to break the chip.

Please refer to the previous article (click the title to read) "The Harm of Residual Chips in the Workpiece and Its Elimination and Discharge Method". Feed and chamfer width (tool wear) Feed is the most influential factor on chip curling and breaking.

If the feed rate is reduced, the thickness of the chip becomes thinner, and it is easy to curl and difficult to break; on the contrary, if the feed rate is increased, the thickness of the chip becomes thicker, and it is easier to break.

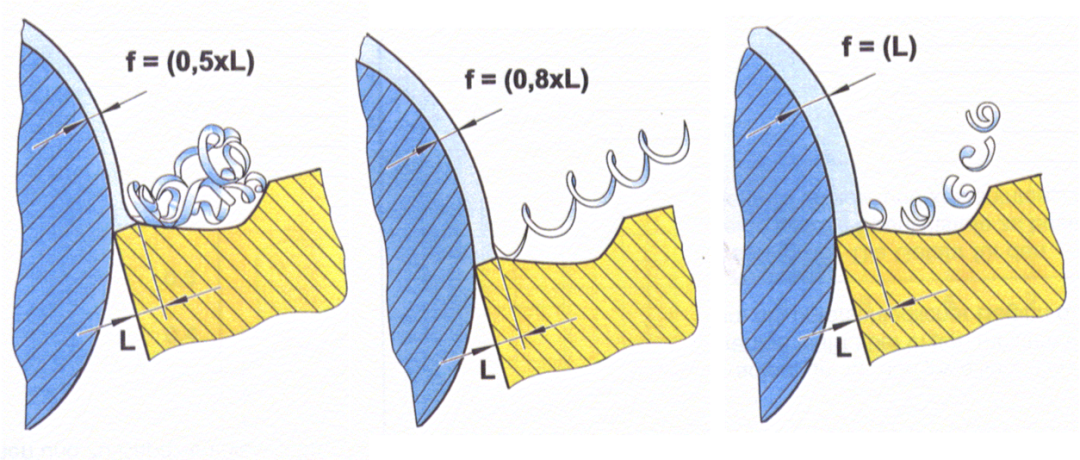

When the tool is worn or the edge is chamfered, the influence on chip breaking is shown in the figure below.

2. Chipbreaker

For finishing/semi-finishing/roughing, choosing the correct geometry also facilitates chip breaking. Due to the limitation of space, we will introduce the chipbreaker in the turning chapter in the special topic "Common Machining Technology" later.

4. Case explanation

Case 1

The first case is the continuous chip problem in the process of blind hole drilling of aluminum parts.

Aluminum is a long-chipping material. The most effective method is CNC pause, which is to divide the original feed length into several segments. After each segment is processed, the rotational speed remains unchanged, but the feed is zero. Because the tool no longer cuts the material , the chips are naturally broken. The other common one is to change the drill bit from a helical groove to a straight groove, which is equivalent to reducing the rake angle.

With the development of laser technology in recent years, concave chip breakers can also be etched on the rake face of the PCD drill reamer. However, it should be pointed out that the problem of continuous chip drilling in drilling requires attention to the location of the chip generation. If the chamfering feature is compounded, the chip shape generated by the chamfering will gradually increase from zero to the required chamfering width.

The constant chip problem when machining chamfering features can usually be solved by adjusting the cutting parameters, or adding a cutting fluid nozzle at the chamfering position to blow off the chips.

Case 2

The second case is the clever use of brushes to solve the problem of chip entanglement in double turret turning.

The conditions encountered by the authors were double turret vertical turning of hardened steel shafts. Hardened steel has high hardness. In order to prevent the cutting edge of the tool from directly contacting the hardened layer and reduce cutting force and cutting vibration, the tool tip is usually buried under the hardened layer of the skin, that is, a relatively small chamfering width is selected. This creates a hidden danger for the constant crumb problem.

During the machining process, the chips are constantly swarfed and wrapped around the workpiece, which will not only scratch the machined surface or the operator-because the chips are the workpiece material that has been "heat-treated" by the cutting heat, the hardness is higher than that of the workpiece surface material- There are also It may be hooked on other accessories of the device, causing an accident. At this time, no matter adjusting cutting parameters or tool chamfering parameters, it will cause changes in the entire processing system and increase unstable factors. After communicating with the same industry, it was found that some manufacturers replaced a steel wire brush on the opposite turret when machining the non-chip tool. The cutting chips that are generated by the tool processing will be intercepted by the brush on the opposite side, and the surrounding of the part cannot be completed. At the same time, the tip can also be cleaned with a brush after processing.

Article summary

Unfortunately, the parts that the author is responsible for are either aluminum or steel, all of which are long-chipping materials. From time to time, the problem of chip breaking occurs. Interested readers will pay attention to it. The author will share what he sees, thinks and gains at any time. Readers are welcome to leave a message about your classic case!