At the request of our readers, we have opened a special topic on common processing techniques. The first one is turning. Turning and its turning tools, we regard it as a classic application, and in the topic "Talking Theory Through Cases", we introduce the contents of tool angle and tool wear.

As the opening work of the topic, the author has been thinking for a long time, hoping to find a mode of introduction: concepts and features, applications, tool types and related knowledge points.

1. Concepts and Features

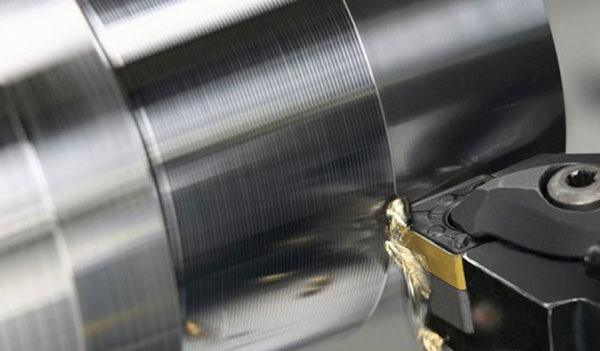

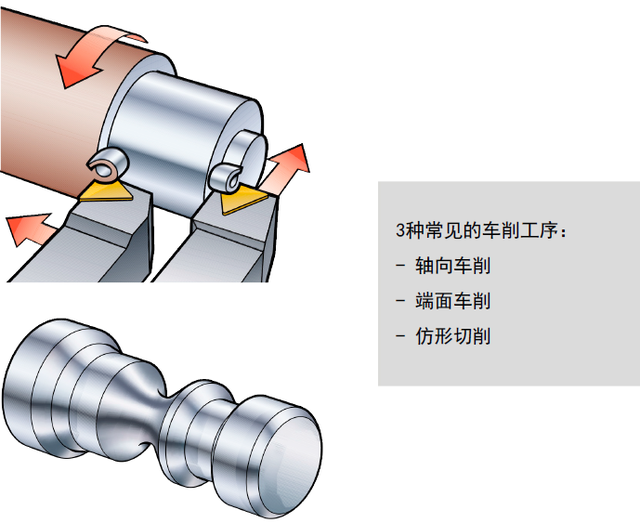

Turning, that is, lathe cutting, is a machining method in which the workpiece is rotated and the tool is fixed. It is usually used to process the outer circle and stepped end face of shaft parts with a fixed center of rotation. What distinguishes turning from other common machining processes is that the workpiece rotates while the tool is stationary.

2. Application occasions

Although drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing on lathes, turning tools are usually used.

The turning tool is the most widely used tool in metal cutting and is the basis for researching other tools. Turning tools can be used on various lathes, and can be used to process outer circles, inner holes, end faces, threads, and various inner and outer revolving body forming surfaces, as well as cutting and grooving. Therefore, there are many types of turning tools, shapes, structures , sizes are also different.

The structural forms of turning tools include integral type, welding type, machine clamp regrinding type and machine clamp indexable type.

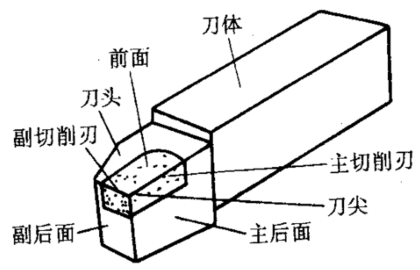

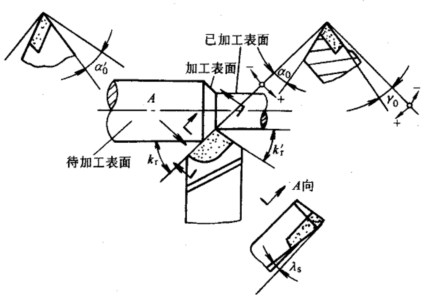

As shown in the figure above, the classic turning tool is divided into two parts: the cutter body and the cutter head. The cutter head is composed of front, main back and secondary back features. The intersection of these features forms the main/minor cutting edge and tool tip, etc. feature.

With the turning occasion, we also introduce machined surfaces and reference planes. Interested readers can read previous articles.

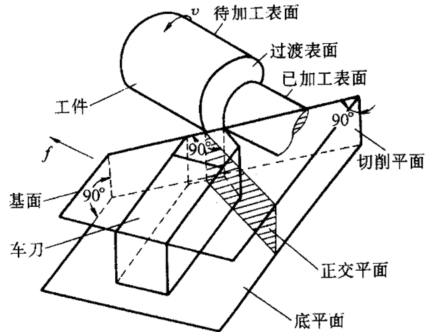

When we explain the tool angle, the case used is also a turning tool. As shown in the figure above, compared with the rotary milling cutter and drill bit, on the fixed turning tool, the rake angle, rear angle, main and auxiliary offset of the tool are explained. Angle and blade inclination, more clear and intuitive.

3. Types of tools

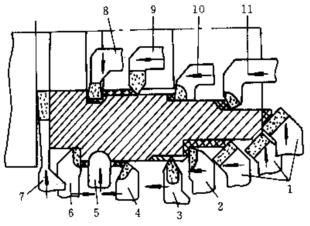

Turning tools can be divided into many types according to different processing characteristics. Common turning tools are shown in the following figure:

1-45° Elbow Turning Tool

2-90° Cylindrical Turning Tool

3-External thread turning tool

4-75° Cylindrical turning tool

5-Forming turning tool

6-90° Cylindrical Turning Tool

7- Cut off knife

8-Inner hole grooving knife

9-Internal thread turning tool

10-Blind hole boring tool

11-Through hole boring tool

4. Relevant knowledge points

chipbreaker

In this chapter, we will introduce the chipbreaker in combination with the turning tool.

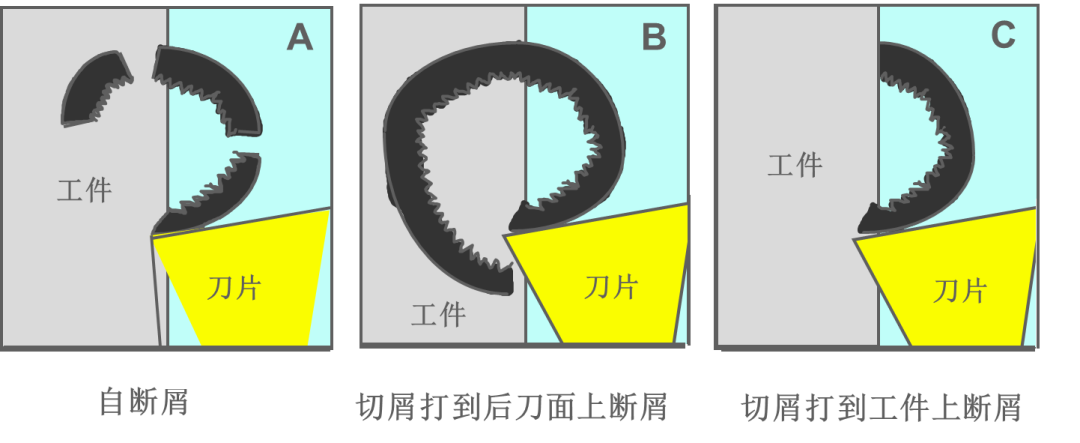

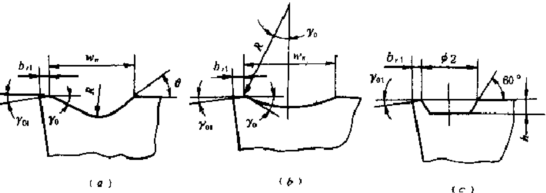

The principle of the chip breaker is to control the flow direction of the chip and appropriately increase the deformation of the chip by pressing or grinding a boss or pit of a specific shape on the rake face, so that the chip can be on the workpiece surface or the tool flank face. Break, or roll the chips into a certain shape.

Basic geometry of common chipbreakers

as the picture shows

The basic cutout is shown in the figure below

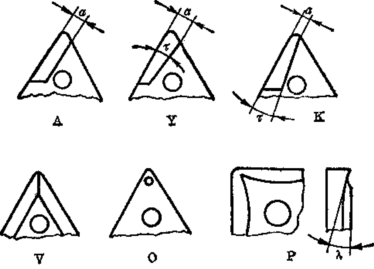

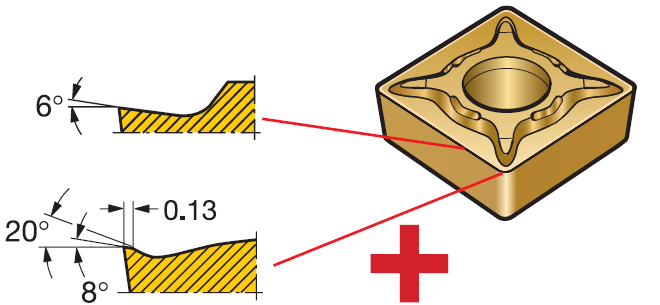

With the popularization and standardization of turning carbide inserts, we no longer need to grind the chip breaker manually. Instead, the manufacturer presses the chip breaker with a fixed shape on the rake face of the insert according to the processing materials and working conditions, and gradually A standard is formed, which results in a more consistent chipbreaker quality.

Wiper

Although wipers are used in processes such as milling, they are more intuitive to explain in turning.

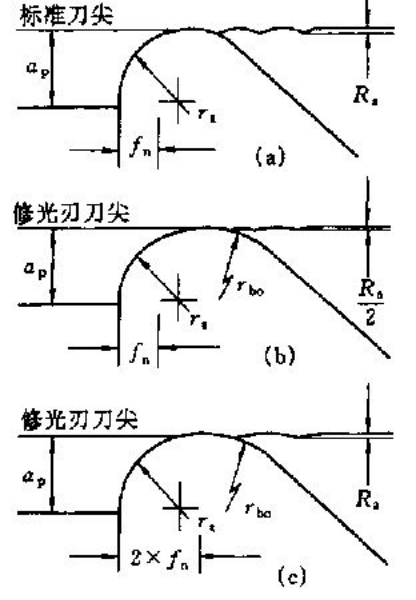

where Figure a represents the standard nose radius and the geometry of the machined surface. According to the definition of surface roughness Ra, in the case of turning, Ra is the height of the "mountain" formed by the shape of the tool tip copied on the machined surface of the workpiece.

Surface roughness can be given by empirical formula.

Ra=f2/(8xr) (where: f is the feed; r is the tool nose radius;)

Decreasing the feed or increasing the nose radius can reduce the surface roughness value, but the former reduces productivity, while the latter increases cutting force.

Without reducing the feed rate but also reducing the surface roughness value, only the angle of the secondary declination is reduced, the purpose is to flatten the height of the "top of the mountain".

Wiper inserts are high-efficiency machining inserts developed based on this idea. The basic design idea is to adjust the geometry of the tip to approximate an elliptical shape within the maximum allowable tip radius tolerance of a standard insert.

Figure b shows the machined surface shape produced by a wiper insert at the same feed as a standard insert. At this time, the machining efficiency is the same as that of standard inserts, but the surface roughness value is reduced by half.

Figure c shows the shape of the machined surface when the wiper insert is cut at twice the feed of the standard insert. Corresponding to Figure b, the surface roughness value is the same at this time, but the processing efficiency is doubled.

Therefore, the advantage of using wiper inserts is that "machining time is halved and surface quality is doubled". In addition, in some cases, the grinding process can be omitted, that is, "grinding by turning" is realized.

The author of this article introduces the basis of cold working technology - turning and its related tools and peripheral knowledge points. In the next article, the author will introduce the built-up tumor, so stay tuned!