First, the definition of thread

Thread refers to a helical, continuous raised portion with a specific cross-section made on the surface of a cylindrical or conical parent body.

Two, common thread classification

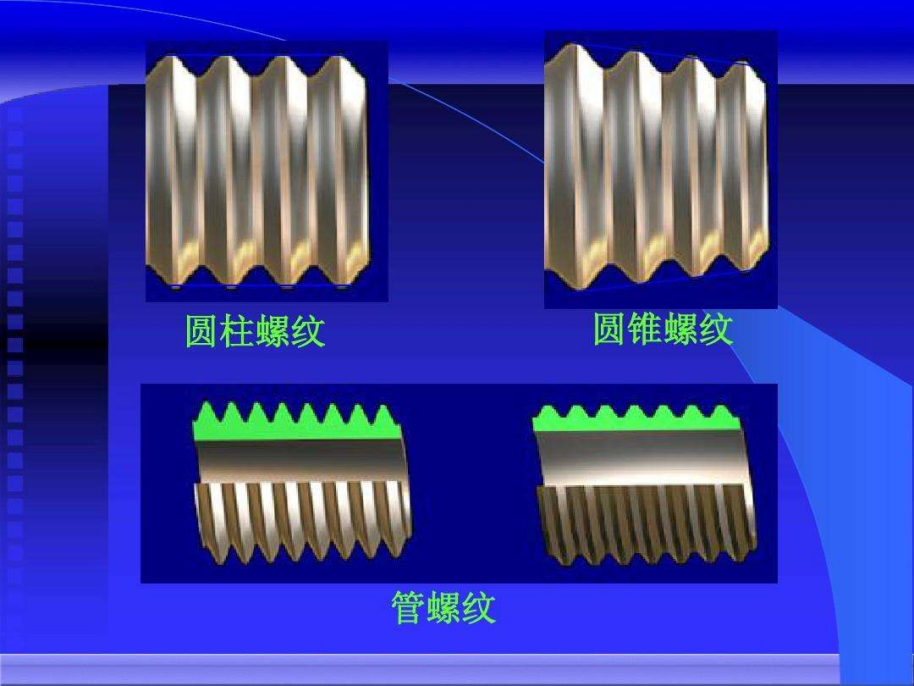

Threads are divided into cylindrical threads and conical threads according to their parent shape.

According to its position in the parent body, it is divided into external thread and internal thread.

The thread must be used in pairs with the inner thread and the outer thread to achieve various predetermined functions, and the mutual sliding contact between the inner thread and the outer thread can play the role of tightening or transmitting motion.

Three, five elements of thread

The thread profile, major diameter, pitch, number and direction of rotation of the thread are called the five elements of the thread.

Only the internal and external threads with the same five elements can be screwed together.

1. Tooth type

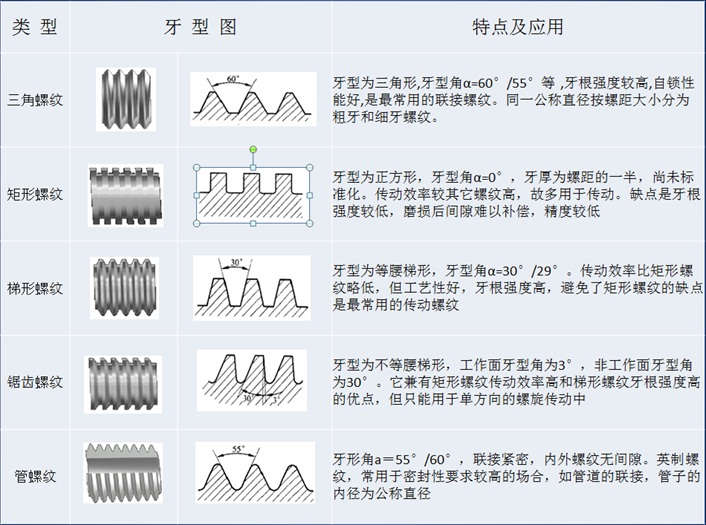

According to its cross-sectional shape (tooth type), it is divided into triangular thread, rectangular thread, trapezoidal thread, serrated thread and other special shape threads.

2. Nominal diameter of thread

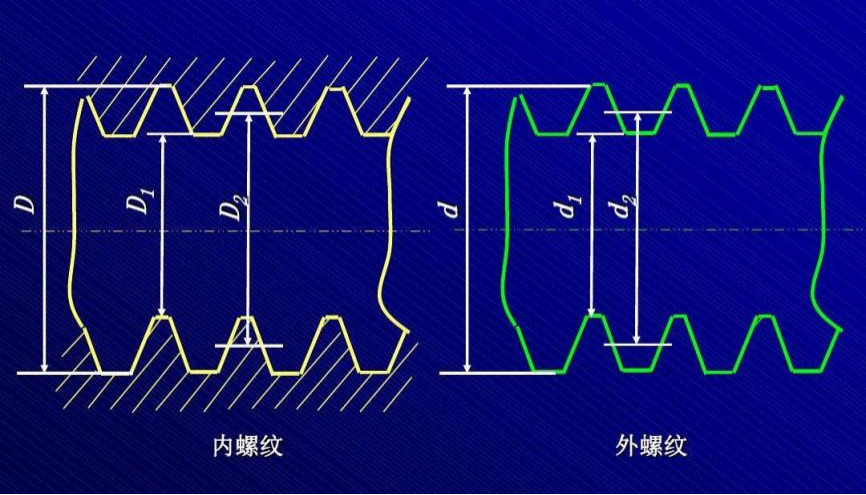

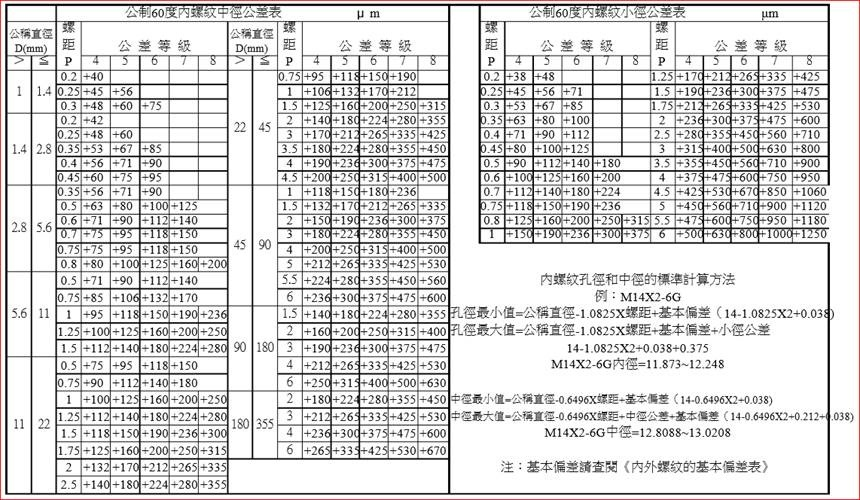

Major diameter - the diameter of the imaginary cylinder that coincides with the crest or the bottom of the external thread (internal and external threads are represented by D and d, respectively). is the nominal diameter of the thread.

Small diameter - the diameter of the imaginary cylinder that coincides with the root of the external thread or the crest of the internal thread (internal and external threads are represented by D1 and d1 respectively).

Middle diameter - between the major diameter and the minor diameter, the diameter of the imaginary cylindrical surface whose generatrix passes through the groove width on the tooth shape and the convex width are equal (internal and external threads are represented by D2 and d2 respectively).

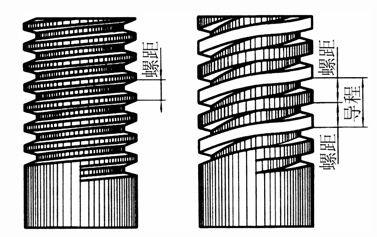

3. Pitch and lead

The axial distance between the corresponding points of two adjacent teeth of the thread is called the pitch, which is represented by P (pitch).

The distance between the axes between two corresponding points on the same thread is called the lead, which is represented by S.

The relationship between lead and pitch is: lead S = pitch P × number of heads n. If it is a single thread, the lead S=pitch P.

4. Number of heads or bars

Threads are divided into single-end and multi-end. A thread formed along a helix is called a single-start thread.

A thread formed along two or more helixes distributed at equal distances in the axial direction is called a multi-start thread.

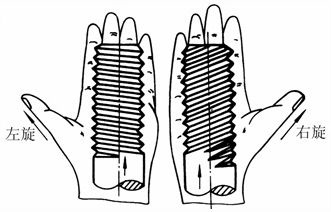

5. Rotation of the thread

The direction in which the thread is screwed in. When the thread is screwed in, if it rotates clockwise, it is right-handed, and if it is counterclockwise, it is left-handed.

If the thread direction is not specified, the default is right thread (usually 95% of the threads we touch are right thread)

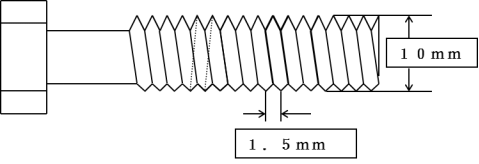

4. Representation of thread specifications

Thread diameter and pitch are in millimeters

Tooth angle 60 degrees

Thread symbol: M

Representation method: thread mark thread outer diameter X thread pitch

Example: M10X1.5

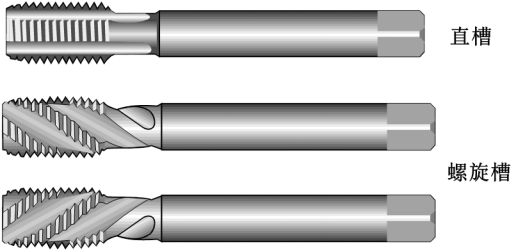

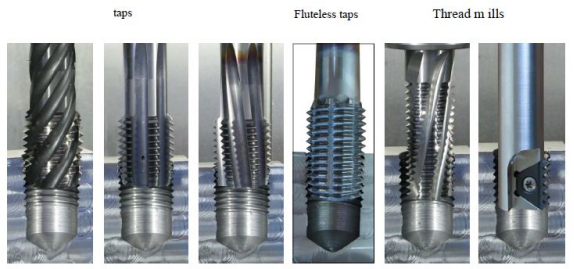

Five, thread processing tools - taps

A tap is a tool for processing internal threads, which can be divided into spiral taps and straight-edged taps according to shape.

According to the use environment, it can be divided into hand taps and machine taps.

According to the specifications, it can be divided into metric, American and inch taps, and according to the origin, it can be divided into imported taps and domestic taps.

Taps are currently the most important tool for manufacturing operators to process threads.

Six, common tap types

Does the tap have its own code name? Hurry up and take notes, or download and bookmark the picture below.

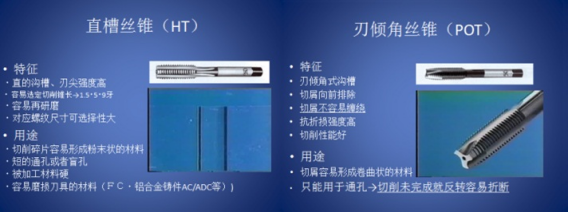

1. HT: straight groove tap

Features: The most common tap, with straight grooves and high point strength.

Advantages: easy to regrind, high economy; large range of thread size and cutting edge length, good versatility.

Uses: Because of the high strength of the tool tip and good impact resistance, it is often used for cutting chip materials (high frequency of cutting periodic impact), materials with high hardness (large cutting load), materials with fast tool wear (requires frequent grinding) or Short through-hole features (frequent access holes).

2. POT: edge inclination tap

Features: With positive edge inclination.

Advantages: Because of the positive edge inclination, the chips are discharged forward; when each cutting tooth of the edge inclination tap cuts in, the cutting layer area gradually increases, and the cutting process is stable; the edge inclination tap is oblique cutting, and the actual cutting rake angle is greater than the nominal rake angle, which increases relative strength of the teeth.

Application: Only for through hole tapping.

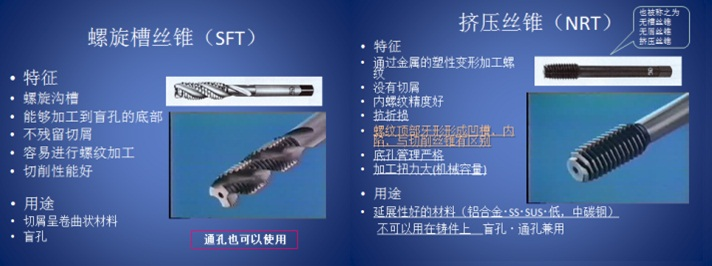

3. Pitch and lead

Features: Spiral flutes

Advantages: The positive rake angle makes cutting easier and has excellent cutting performance; the rear chip removal function brought by the helical groove makes it suitable for blind hole processing.

Application: Blind hole processing.

4. NRT: extrusion tap

Feature: No chip flutes

Advantages: The thread is formed by plastic deformation of the metal, so no chips are produced, and there is no trouble in chip removal; the thread is extruded and has high strength.

Application: Only internal thread, blind hole through hole is applicable; the workpiece material must be a material with good ductility.

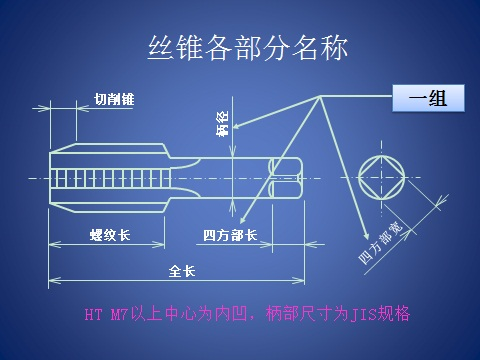

Seven, tap structure parameters

As shown in the figure above, the tap is relatively simple in functional structure, including a cutting cone and a shank, wherein cutting and forming the thread is the cutting cone of the tap.

Due to space limitations, the impact of cutting cones on cutting performance will be introduced in the next article.

On the basis of the basic parameters of thread introduced in this article, in the next article, the author will introduce the key parameters of thread tool-tap and its influence on cutting performance, so stay tuned.