In the previous article, the author introduced the types and characteristics of water-soluble cutting fluids. Just as a tool wears out and fails, so does the cutting fluid: that is, it cannot perform its intended function. In this article, the author will refer to relevant materials to introduce the problems and countermeasures of the use of cutting fluid.

In this article, the author will first point out four common problems in the use of water-soluble cutting fluids, namely deterioration and odor, corrosion, foaming, and skin allergy of the operator, and then discuss the "key four factors that affect the performance of water-soluble cutting fluids". ” and how it affects it, and you are welcome to read it.

Q: Why does the cutting fluid deteriorate and stink?

A: The root cause is that the cutting fluid contains a lot of bacteria.

The bacteria in cutting fluid are mainly aerobic and anaerobic bacteria.

Oxygen-consuming bacteria live in an environment with minerals, such as water, concentrate of cutting fluid and oil leaked from machine tools, and are divided into two parts every 20-30 minutes under aerobic conditions.

The anaerobic bacteria live in an environment without oxygen, which is divided into two parts every hour, and metabolizes to release S02, which has irritating gas and makes the cutting fluid black.

On this basis, when the bacteria in the cutting fluid is greater than 106, the cutting fluid will become smelly.

Q: How to control bacterial growth?

answer:

1. Use the original cutting fluid with high quality and good stability.

2. Using pure water to prepare the concentrate is not only easy to prepare, but also can improve the lubricity of the cutting fluid and prevent bacterial erosion.

3. When using, it is necessary to control the concentration of the concentrate in the cutting fluid not to be too low, otherwise it is easy for bacteria to grow.

4. Since the oil used in the machine tool contains bacteria, it is necessary to minimize the oil leaking from the machine tool to mix into the cutting fluid.

5. When the pH value of the cutting fluid is in the range of 8.3-9.2, it is difficult for bacteria to survive, so new cutting fluid should be added in time to stabilize the pH value.

6. Keep the cutting fluid clean, and do not mix dirty oil, food, tobacco and other contaminants into the cutting fluid.

7. Frequent use of fungicides.

8. Keep the workshop and machine tools clean.

9. If the equipment does not have a filter device, it should regularly skim off the oil and remove the dirt.

Q: Why is cutting fluid corrosive?

Answer: The most likely reason for the corrosiveness of cutting fluid is that the proportion of concentrated fluid in the cutting fluid is low, resulting in too high or too low pH of the cutting fluid. For example, when pH>9.2, the cutting fluid has a corrosive effect on aluminum. Therefore, the appropriate pH value should be selected according to the metal material being processed.

Q: How to prevent the corrosiveness of cutting fluid?

answer:

1. Use pure water to prepare cutting fluid, and the concentration of cutting fluid should be controlled within the recommended range in the instruction manual of the cutting fluid used.

2. If necessary, use anti-rust fluid.

3. Control the number of bacteria and avoid the production of bacteria.

4. Check the humidity, and pay attention to control the humidity of the working environment within an appropriate range.

5. Avoid contamination of cutting fluid by other sources.

Q: Why does the cutting fluid produce foam?

Answer: There are many reasons for this problem:

1. The liquid level of the cutting fluid is too low. The cutting fluid foams due to impact during circulation.

2. The flow rate of the cutting fluid is too fast, and the bubbles have no time to overflow, and the accumulation will accumulate, resulting in the retention of a large amount of foam.

3. Too many right angles are included in the design of the cutting fluid tank, or the angle at which the cutting fluid flows out of the nozzle is perpendicular to the liquid surface.

Q: How to avoid foaming?

answer:

1. In the centralized cooling system, the pipelines are designed to be cascaded in series, and the pipeline pressure near the cooling box should be lower.

2. Ensure that the liquid level of the cutting fluid is not too low, check the liquid level in time, and replenish the cutting fluid.

3. Control the flow rate of cutting fluid not too fast.

4. When designing the sink, it should be noted that there are not too many right angles in the sink.

5. When using cutting fluid, it should be noted that the angle of the cutting fluid nozzle is not too straight.

Q: Will the cutting fluid cause skin irritation to the operator?

Answer: The cause of allergens may be that the pH value of the concentrate is too high due to the excessive use of the concentrate, or the components of the cutting fluid, such as fungicides, contain ingredients that cause skin allergies to the operator.

The allergen may also be the protective suspension layer on the surface of the cutting fluid, such as odor blocking layer, anti-foam layer.

Q: How to avoid operator skin allergies?

answer:

1. The operator should apply protective oil, wear work clothes and gloves, and should avoid direct contact between the skin and the cutting fluid.

2. The proportion of concentrate in cutting fluid should be controlled within the recommended range of cutting fluid.

3. The use of fungicides should be in accordance with the dosage recommended in the instructions.

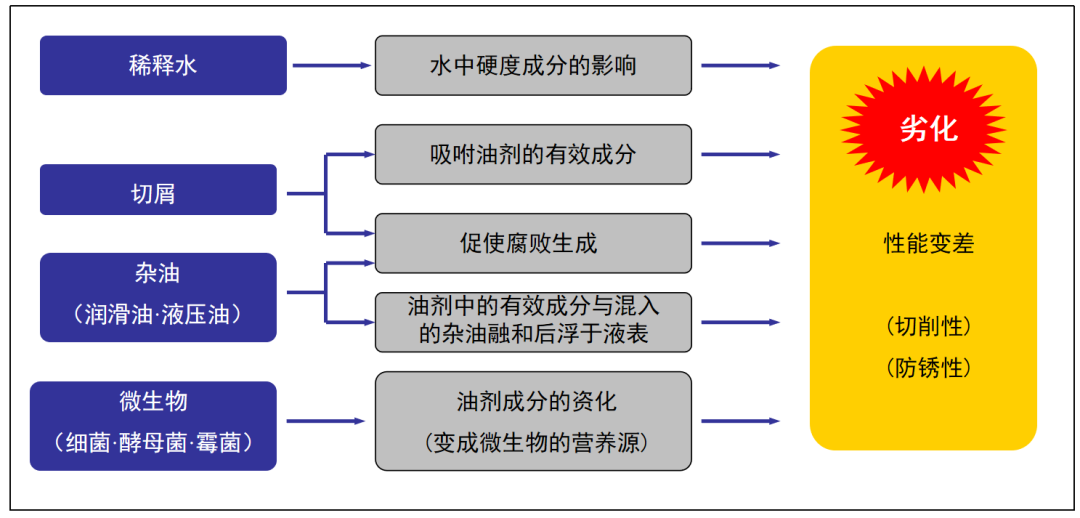

Readers who have patiently read the Q&A above will surely find that some factors recur in the responses to the four questions. These are dilution water, cuttings, miscellaneous oils and microorganisms. The author consulted the technicians of an imported brand in the cutting fluid industry on this issue, and obtained the following dry goods, which are called the "key four factors" affecting the performance of cutting fluids:

Factor 1: Dilution water and its effects

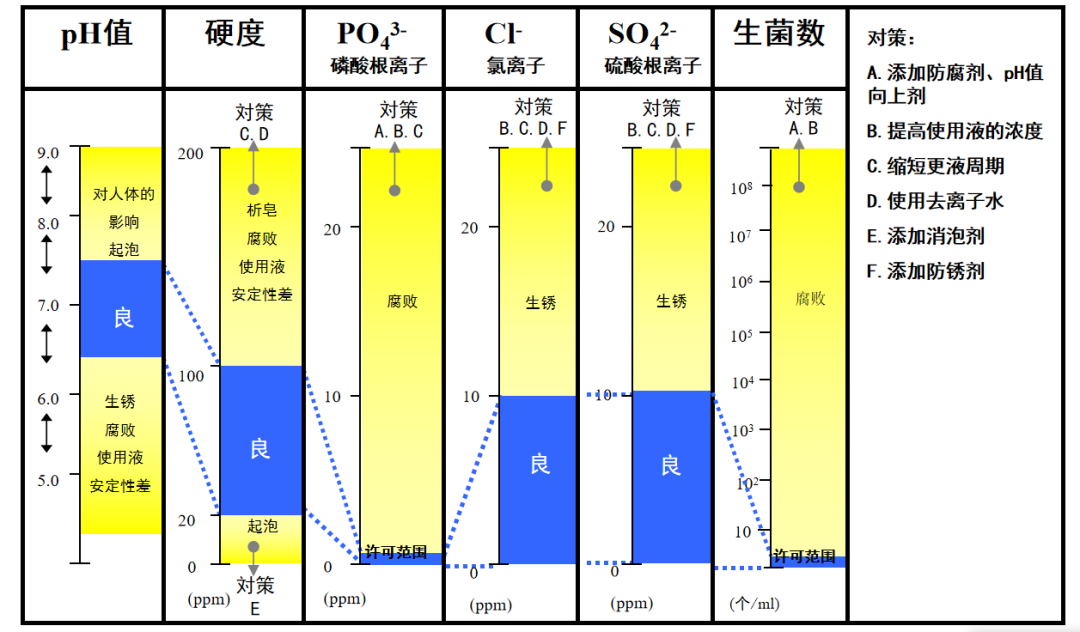

First, let's take a look at the effect of dilution water on cutting fluid indicators such as pH value:

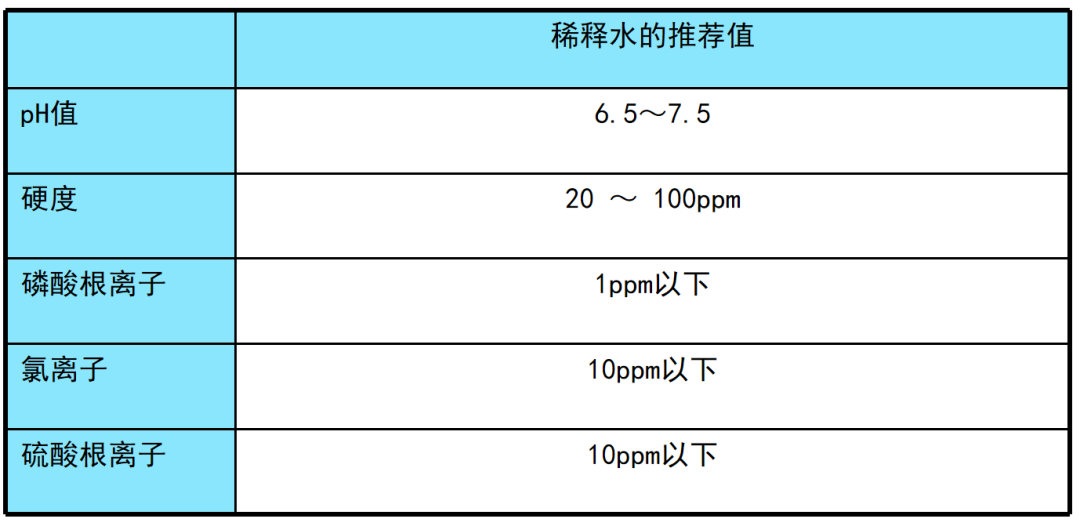

The recommended dilution water indicators are shown in the following table:

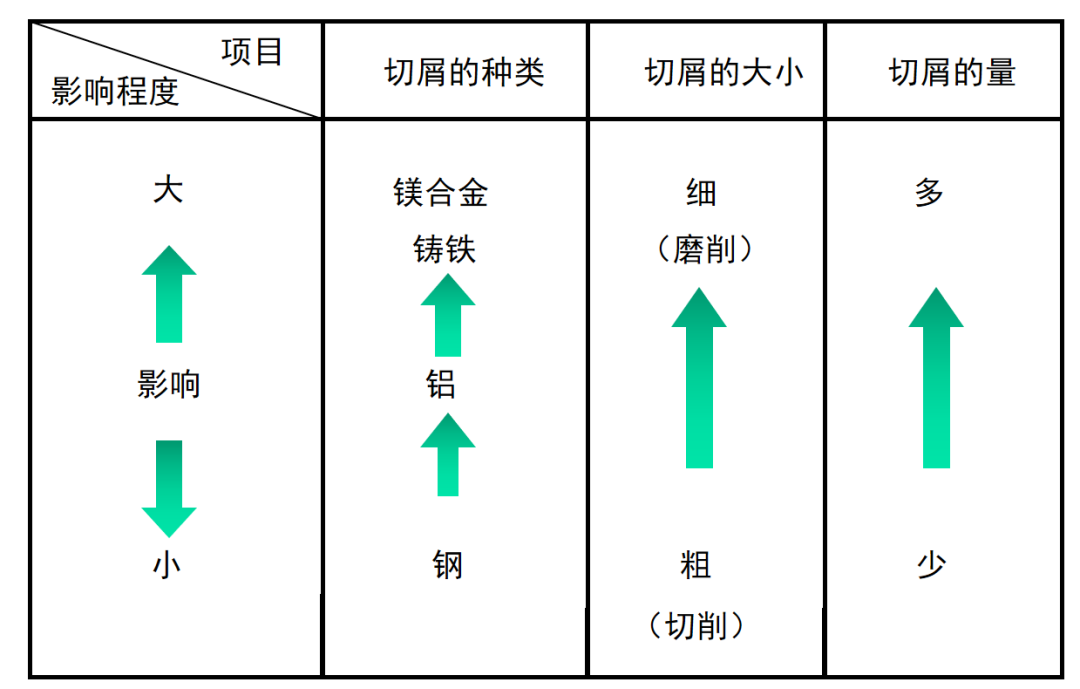

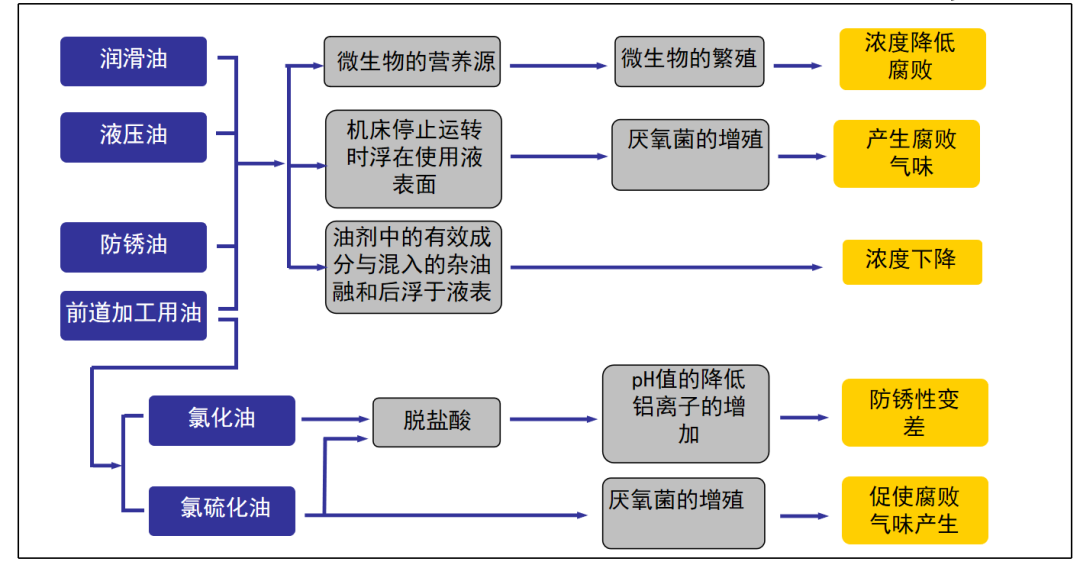

Factor 2: Chips and their effects

Factor three: miscellaneous oil and its influence

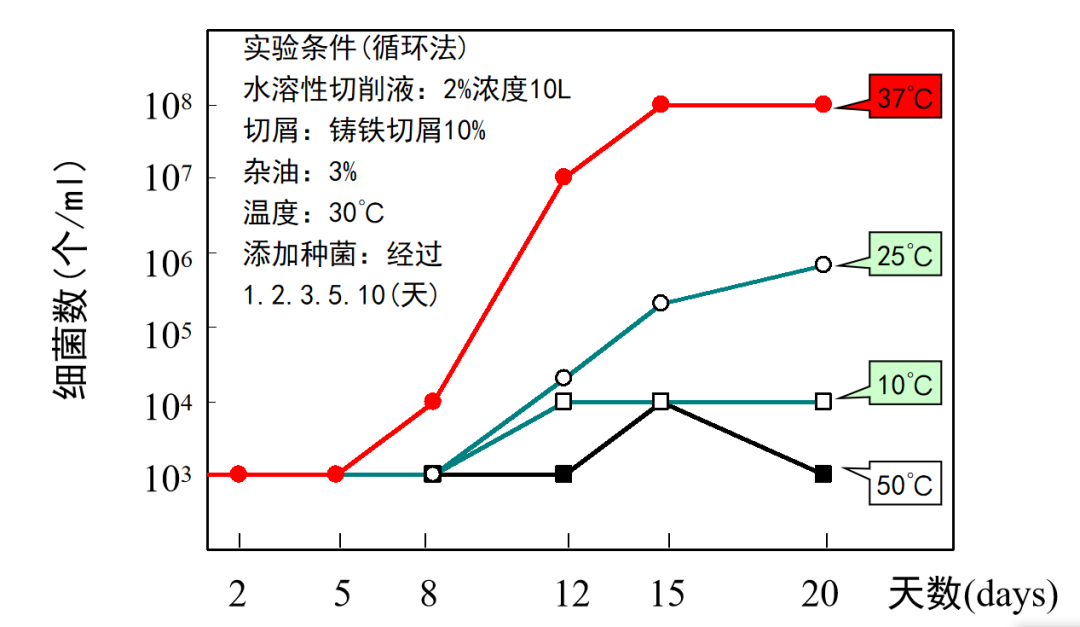

Factor 4: Microorganisms and their effects

The relationship between bacterial reproduction and temperature

References

"Metal Working Fluid Usage Guide", an authoritative book recommended in the industry, can be read by readers who are eager to learn more. "A Brief Discussion on Cutting Fluids for Metal Cutting", a journal paper explained in simple terms, systematically introduces the classification, selection and management of cutting fluids, including issues such as bacteriostasis, anticorrosion, foaming, and operator skin allergies. "Management of the Use Process of Water-Soluble Cutting Fluid", a highly directional journal paper, briefly introduces the concentration of water-soluble cutting fluid and the necessity of anti-corrosion management and its management methods.