In the last article, the author introduced the basic knowledge of milling. In this article, the author will talk to you about "milling things"

1. Selection of the number of teeth of the milling cutter

The milling cutter has a large number of teeth, which can improve production efficiency. However, due to the limitation of chip space, cutter tooth strength, machine power and rigidity, etc., the number of teeth of indexable milling cutters of different diameters has corresponding regulations.

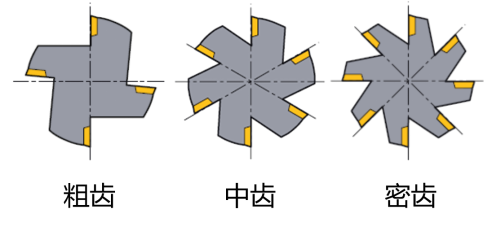

In order to meet the needs of different users, indexable milling cutters with the same diameter generally have three types: coarse tooth, medium tooth and dense tooth.

When choosing the number of teeth, the rigidity and load of the machine tool should be considered first. If the number of teeth is too high, the cutting force will be large, which will lead to overloading of the equipment or deformation of the workpiece.

Secondly, it is necessary to consider the load on the cutting edge of the tool and chip removal, refer to the principle of the recommended feed per tooth of the tool, and judge whether there is a chip removal problem according to the processing quality.

2. Comparison of dry and wet processing

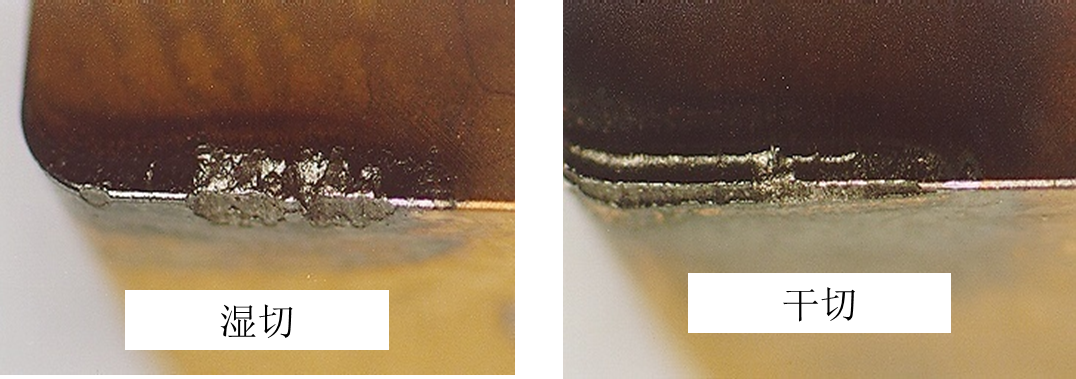

Dry cutting is a processing technology that does not use or use a small amount of cutting fluid in the processing process, and a clean and environmentally friendly manufacturing process that controls environmental pollution from the source.

Some people think that compared to continuous turning, interrupted milling seems to be more suitable for dry cutting technology, not only do not have to worry about chip breaking problems, but also can reduce the thermal shock applied to the cutting edge, alternating hot and cold.

However, experiments show that the life of dry cutting tool is significantly lower than that of wet cutting, and the cutting edge is mainly damaged.

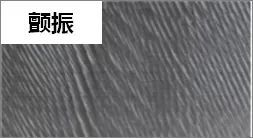

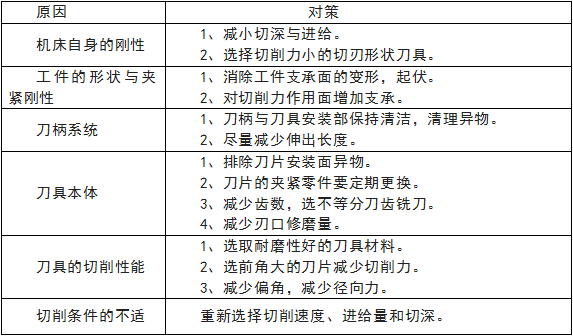

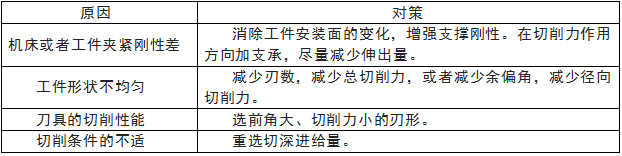

3. Causes and countermeasures of flutter vibration

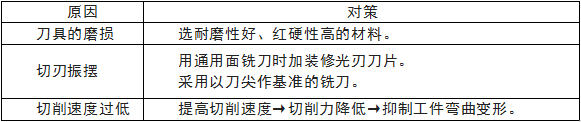

4. Reasons and countermeasures for poor roughness

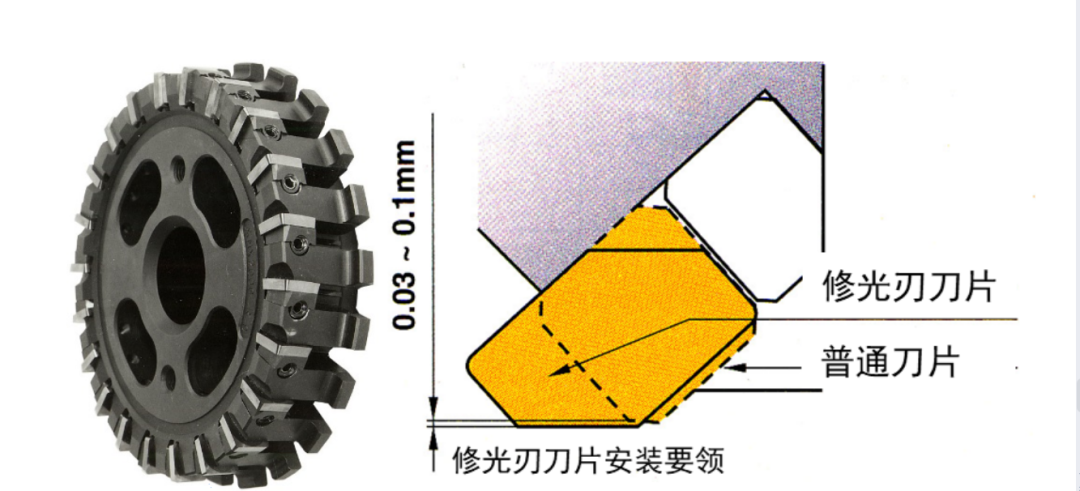

Correct use of the wiper blade can improve the surface roughness. It should be noted that the height difference of the wiper blade relative to the ordinary blade.

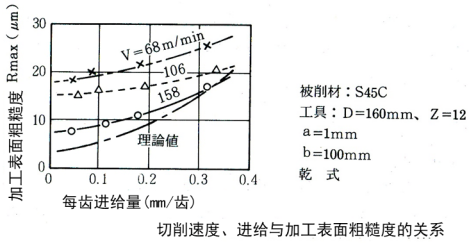

Referring to the experimental data, as shown in the figure below, the cutting speed increases, the surface roughness decreases, the feed per tooth is too high, and the surface roughness deteriorates.

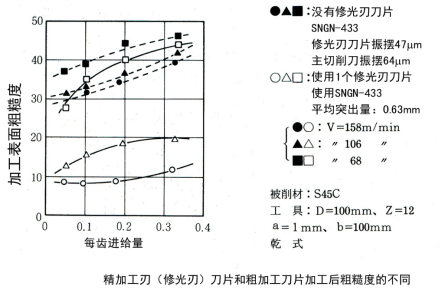

The "wiper edge effect" and "cutting parameter effect" are designed into the same experiment, and the comparison results of the factors are shown in the figure below.

5. Causes and countermeasures of concentration

Waviness refers to an index to measure the height fluctuation of the workpiece surface, usually refers to the height difference between the highest point and the lowest point in the measurement plane, as shown in the figure below.

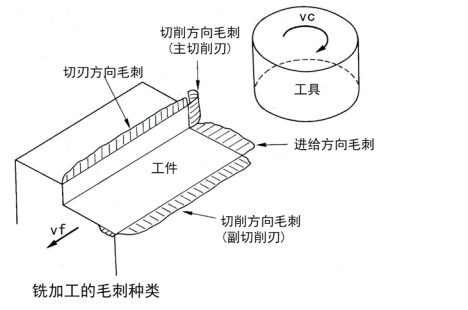

6. Causes and countermeasures of burrs

When milling a plane, affected by the machining path and intermittent machining, different degrees of flanging and burrs will be generated, as shown in the figure below.

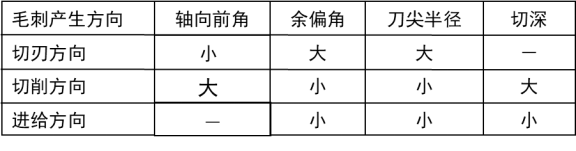

Correspondingly, the relationship between milling tool parameters and flanging burr is shown in the following figure:

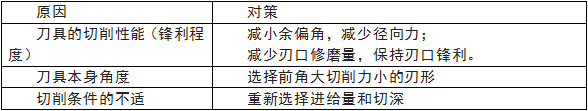

The causes and countermeasures of flanging burrs are shown in the following table:

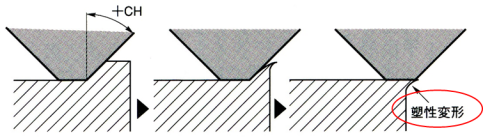

Especially when processing materials with lower hardness, at the edge position, the uncut material will deform and form flanging, as shown in the figure below.

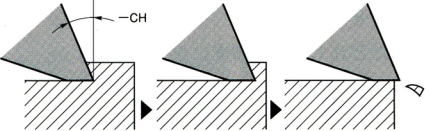

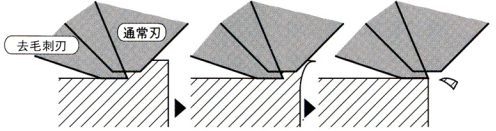

Here is a "deburring edge", the principle of which is to increase the rake angle of the blade in order to reduce the cutting force and cut off the edge metal material instead of extruding it into a flanging, as shown in the figure below.

Due to the poor strength of the cutting edge, the deburring edge can be processed in combination with the usual edge, and the effect is good. For example, the wiper blade that forms the final surface is designed with a large positive rake angle to realize the function of "deburring edge".

The introduction of this "deburring edge" is only to expand the angle of everyone's problem-solving, but the author believes that the application of large rake angle inserts in the actual processing process, especially in intermittent cutting and strong impact milling, the effect is not necessarily ideal.

Readers interested in such issues can read the previous article "EOS Theory of Milling Burr Removal"

As a generalist in common processing methods, milling has a wide range of applications. Based on his own experience, the author lists several common problems and their countermeasures for your reference. In the next article, the author will focus on the failure modes of milling tools and their countermeasures, so stay tuned